Experimental Development of Fuzzy Controllers for Thermal and Pneumatic Processes

Main Article Content

Keywords

Raspberry Pi, Control System, Instrumentation, Fuzzy, Python

Abstract

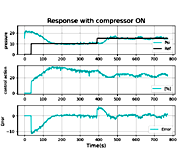

In this project, a Fuzzy control system is proposed in an industrial process training module with two independent systems between them, one thermal and the other pneumatic. The control algorithm is developed in Python language v3.6 executed by a Raspberry Pi B+, both controllers depend on the error and change in error that are updated in times of 2 s and 1 s, for temperature and pressure respectively, communication with the plants uses A/D and D/A converters, the thermal Fuzzy was analyzed with three temperature references [50,100 and 150]°C, with a rise time of 191 s, 360 s and 505 s; steady state error of 5.5%, 0.7% y 0.7%, in the pneumatic system the speed of change between references is evaluated from 10 psi to 15 psi varying the activation of the compressor at the beginning of the experiments, the settling times obtained are 111 s and 106 s, with the compressor off the result is 116 s and 88 s, besides a maximum excess of 13% with inherent oscillations to the type system that are in an acceptable range.

Downloads

References

[2] H. J. Ferreau, S. Almér, R. Verschueren, M. Diehl, D. Frick, A. Domahidi, J. L. Jerez, G. Stathopoulos, and C. Jones, “Embedded optimization methods for industrial automatic control,” IFAC-PapersOnLine, vol. 50, no. 1, pp. 13 194–13 209, 2017, https://doi.org/10.1016/j.ifacol.2017.08.1946.

[3] F. Ponci, A. Sadu, R. Uhl, M. Mirz, A. Angioni, and A. Monti, “Instrumentation and measurement testing in the real-time lab for automation of complex power systems,” IEEE Instrumentation & Measurement Magazine, vol. 21, no. 1, pp. 17–24, 2018, https://doi.org/10.1109/MIM.2018.8278805.

[4] E. Harper, Elementos del control de procesos. Limusa noriega editores, 2015, ch. 1, pp. 11–51.

[5] J. Huo, F. T. Chan, C. K. Lee, J. O. Strandhagen, and B. Niu, “Smart control of the assembly process with a fuzzy control system in the context of industry 4.0,” Advanced Engineering Informatics, vol. 43, p. 101031, 2020.

[6] J. L. Riviello, E. L. Riviello, J. H. Reyes, and C. G. Escarpeta, “Implementation of fuzzy controller in different embedded systems,” in 2019 IEEE International Conference on Engineering Veracruz (ICEV), vol. 1. IEEE, 2019, pp. 1–4, https://doi.org/10.1109/ICEV.2019.8920584.

[7] R. P. FOUNDATION. (2015) Raspberry pi 2 model b. https://www. raspberrypi.org/products/raspberry-pi-2-model-b/

[8] J. Li, Q. Xiong, K. Wang, X. Shi, and S. Liang, “A recurrent self-evolving fuzzy neural network predictive control for microwave drying process,” Drying Technology, vol. 34, no. 12, pp. 1434–1444, 2016, https://doi.org/10.1080/07373937.2015. 1122612.

[9] J. M. Celis-Peñaranda, C. D. Escobar-Amado, S. B. Sepúlveda-Mora, S. A. Castro-Casadiego, B. Medina-Delgado, and J. J. Ramírez-Mateus, “Control adaptativo para optimizar una intersección semafórica basado en un sistema embebido,” Ingeniería y ciencia, vol. 12, no. 24, pp. 169–193, 2016, https://doi.org/10. 17230/ingciencia.12.24.8.

[10] P. Navdeti, S. Parte, P. Talashilkar, J. Patil, and V. Khairnar, “Patient parameter monitoring system using raspberry pi,” International Journal Of Engineering And Computer Science, vol. 5, no. 3, 2016, https://doi.org/10.1109/ICCTIDE. 2016.7725378.

[11] G. Macias-Bobadilla, J. Becerra-Ruiz, A. A. Estévez-Bén, and J. Rodríguez- Reséndiz, “Fuzzy control-based system feed-back by obd-ii data acquisition for complementary injection of hydrogen into internal combustion engines,” International Journal of Hydrogen Energy, 2020, https://doi.org/10.1016/j.ijhydene.2020. 07.084.

[12] J. R. García-Martínez, E. E. Cruz-Miguel, R. V. Carrillo-Serrano, F. Mendoza-Mondragón, M. Toledano-Ayala, and J. Rodríguez-Reséndiz, “A pid-type fuzzy logic controller-based approach for motion control applications,” Sensors, vol. 20, no. 18, p. 5323, 2020, https://doi.org/10.3390/s20185323. 99

[13] U. Zalabarria, E. Irigoyen, R. Martinez, M. Larrea, and A. Salazar-Ramirez, “A low-cost, portable solution for stress and relaxation estimation based on a real-time fuzzy algorithm,” IEEE Access, vol. 8, pp. 74 118–74 128, 2020, https://doi.org/10.1109/ACCESS.2020.2988348.

[14] H. Fakhrurroja, S. A. Mardhotillah, O. Mahendra, A. Munandar, M. I. Rizqyawan, and R. P. Pratama, “Automatic ph and humidity control system for hydroponics using fuzzy logic,” in 2019 International Conference on Computer, Control, Informatics and its Applications (IC3INA). IEEE, 2019, pp. 156–161, https://doi.org/10.1109/IC3INA48034.2019.8949590.

[15] M. J. Villaseñor-Aguilar, J. E. Botello-Álvarez, F. J. Pérez-Pinal, M. Cano- Lara, M. F. León-Galván, M.-G. Bravo-Sánchez, and A. I. Barranco- Gutierrez, “Fuzzy classification of the maturity of the tomato using a vision system,” Journal of Sensors, vol. 2019, 2019, https://doi.org/10.1155/2019/3175848.

[16] M. Das, V. Sivakami, A. Pal, and B. Vasuki, “Analog-digital conditioning circuit for rtd temperature measurement,” in 2018 15th IEEE India Council International Conference (INDICON). IEEE, 2018, pp. 1–5, https://doi.org/10.1109/ INDICON45594.2018.8987077

[17] A. Rai and D. Yadav, “Evaluating wiring configurations for rtd sensor in temperature measurement,” I-Manager’s Journal on Electronics Engineering, vol. 10, no. 1, p. 1, 2019, https://doi.org/10.26634/jele.10.1.16422.

[18] RTD-to-Digital Converter, maxim integrated, 07 2015, rev. 3.

[19] Transmisor de presión para aplicaciones generales industriales. Tipo MBS 3000 y MBS 3050, Danfoss, 09 2013.

[20] F. Kurokawa and S. Hattori, “Single stage ad-dc full-bridge converter for battery charger,” in 2015 IEEE International Telecommunications Energy Conference (INTELEC). IEEE, 2015, pp. 1–6, https://doi.org/10.1109/INTLEC.2015. 7572402.

[21] R. Skrbina and D. Team, “Filtered pwm digital to analog converter,” Design team, vol. 10, no. 4, 2015.

[22] E. A. W. Hung T. Nguyen, Carol L. Walker, FUZZY MODELING AND CONTROL. CRC Press, 2018, ch. 13, pp. 385–399.

[23] H.-R. Lin, B.-Y. Cao, and Y.-z. Liao, “Fuzzy control,” in Fuzzy Sets Theory Preliminary. Springer, 2018, pp. 73–108, https://doi.org/10.1007/978-3-319-70749-5_3.

[24] G. Yang, J.-M. Du, X.-Y. Fu, and B.-R. Li, “Asymmetric fuzzy control of a positive and negative pneumatic pressure servo system,” Chinese Journal of Mechanical Engineering, vol. 30, no. 6, pp. 1438–1446, 2017, https://doi.org/10.1007/ s10033-017-0194-1.

[25] C.Wang, “A study of membership functions on mamdani-type fuzzy inference system for industrial decision-making,” 2015.

[26] O. A. M. Ali, A. Y. Ali, and B. S. Sumait, “Comparison between the effects of different types of membership functions on fuzzy logic controller performance,” International Journal, vol. 76, pp. 76–83, 2015, Corpus ID:736797.

[27] Y.-J. Wang, “Ranking triangle and trapezoidal fuzzy numbers based on the relative preference relation,” Applied mathematical modelling, vol. 39, no. 2, pp. 586–599, 2015, https://doi.org/10.1016/j.apm.2014.06.011.

[28] S. B. Zdenko Kovaˆcic, Fuzzy Controller Design. CRC Press, 2006, ch. 2, pp. 9–70.

[29] D. K. Sambariya and R. Prasad, “Selection of membership functions based on fuzzy rules to design an efficient power system stabilizer,” International Journal of Fuzzy Systems, vol. 19, no. 3, pp. 813–828, 2017, https://doi.org/10.1007/ s40815-016-0197-6

[30] D. Vyas, Y. Misra, and H. Kamath, “Comparison and analysis of defuzzification methods of a fuzzy controller to maintain the cane level during cane juice extraction,” in 2015 International Conference on Signal Processing and Communication Engineering Systems. IEEE, 2015, pp. 102–106, https://doi.org/10.1109/SPACES.2015.7058225.

[31] J. Warner, J. Sexauer, scikit fuzzy, twmeggs, alexsavio, A. Unnikrishnan, G. Castelão, F. A. Pontes, T. Uelwer, pd2f, laurazh, F. Batista, alexbuy, W. V. den Broeck, W. Song, T. G. Badger, R. A. M. Pérez, J. F. Power, H. Mishra, G. O. Trullols, A. Hörteborn, and 99991, “scikit-fuzzy/scikitfuzzy: Scikit-fuzzy 0.4.2,” Nov. 2019, https://doi.org/10.5281/zenodo.3541384.

[32] S. Agapiou, O. Papaspiliopoulos, D. Sanz-Alonso, A. Stuart et al., “Importance sampling: Intrinsic dimension and computational cost,” Statistical Science, vol. 32, no. 3, pp. 405–431, 2017, https://doi.org/10.1214/17-STS611.

[33] D. Kim, J. Cai, K. B. Ariyur, and J. E. Braun, “System identification for building thermal systems under the presence of unmeasured disturbances in closed loop operation: Lumped disturbance modeling approach,” Building and Environment, vol. 107, pp. 169–180, 2016, https://doi.org/10.1016/j.buildenv.2016. 07.007.

[34] D. S. Bhandare and N. Kulkarni, “Performances evaluation and comparison of pid controller and fuzzy logic controller for process liquid level control,” in 2015 15th International Conference on Control, Automation and Systems (ICCAS). IEEE, 2015, pp. 1347–1352, https://doi.org/10.1109/ICCAS.2015.7364848