Secado por atomización de bacterias ácido lácticas una revisión

Main Article Content

Keywords

Secado por atomización, bacterias ácido lácticas, cultivos iniciadores, probióticos, viabilidad

Resumen

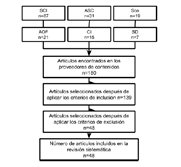

Las bacterias ácido lácticas (BAL) son microorganismos que se utilizan como cultivos iniciadores o probióticos, los cuales son de interés en la industria alimentaria y farmacéutica. La preservación de las BAL por diferentes métodos de secado es un tema que ha cobrado interés debido al aumento en la demanda de estos microorganismos. El secado por atomización es un método eficaz que permite obtener productos a bajo costo, con relación al secado por liofilización el cual es comúnmente utilizado para estos microorganismos. El objetivo de esta revisión sistemática es presentar de forma organizada los artículos científicos que han sido publicados en procesos de secado por atomización empleando bacterias ácido lácticas (BAL). La metodología utilizada en la búsqueda y selección de los artículos brinda una exploración durante el periodo 2009- 2019. Los resultados de los diferentes artículos consultados se compararon estableciendo las similitudes metodológicas, se discuten los principales microorganismos estudiados, así como los agentes protectores empleados para mejorar la viabilidad durante el secado por atomización, las condiciones y escala de los equipos de secado por atomización y finalmente las características de los productos secos obtenidos. La información aquí compilada brinda unabase para ajustar la metodología de trabajo cuando se propongan procesos de secado por atomización para BAL.

Descargas

Referencias

[2] J. Burgain, C. Gaiani, M. Linder, and J. Scher, “Encapsulation of probiotic living cells: From laboratory scale to industrial applications,” Journal of Food Engineering, vol. 104, no. 4, pp. 467–483, 2011. [Online]. Available: http://dx.doi.org/10.1016/j.jfoodeng.2010.12.031

[3] C. Iyer and K. Kailasapathy, “Effect of co-encapsulation of probiotics with prebiotics on increasing the viability of encapsulated bacteria under in vitro acidic and bile salt conditions and in yogurt,” Journal of Food Science, vol. 70, no. 1, pp. M18–M23, 2005. [Online]. Available: http://dx.doi.org/10.1111/j.1365-2621.2005.tb09041.x

[4] M. I. Santos, C. Araujo-Andrade, E. Esparza-Ibarra, E. Tymczyszyn, and A. Gómez-Zavaglia, “Galacto-oligosaccharides and lactulose as protectants against desiccation of Lactobacillus delbrueckii subsp. bulcaricus,” Biotechnology Progress, vol. 30, no. 5, pp. 1231–1238, 2014. [Online]. Available: http://dx.doi.org/10.1002/btpr.1969

[5] WHO, “Probiotics in food; Health and nutritional properties and guidelines for evaluation,” Tech. Rep., 2001.

[6] S. Huang, M. L. Vignolles, X. D. Chen, Y. Le Loir, G. Jan, P. Schuck, and R. Jeantet, “Spray drying of probiotics and other food-grade bacteria: A review,” Trends in Food Science and Technology, vol. 63, pp. 1–17, 2017. [Online]. Available: http://dx.doi.org/10.1016/j.tifs.2017.02.007

[7] S. Tantratian, S. Wattanaprasert, and S. Suknaisilp, “Effect of partial substitution of milk-non-fat with xanthan gum on encapsulation of a probiotic Lactobacillus,” Journal of Food Processing and Preservation, vol. 42, no. 7, pp. 1–7, 2018. [Online]. Available: http://dx.doi.org/10.1111/ jfpp.13673

[8] H. A. Albadran, A. Chatzifragkou, V. V. Khutoryanskiy, and D. Charalampopoulos, “Stability of probiotic Lactobacillus plantarum in dry microcapsules under accelerated storage conditions,” Food Research International, vol. 74, pp. 208–216, 2015. [Online]. Available: http://dx.doi.org/10.1016/j.foodres.2015.05.016

[9] M. de la protección social, “Resolución Número 333 de 2011,” República de Colombia, Bogotá, Tech. Rep., 2011.

[10] H. Velly, F. Fonseca, S. Passot, A. Delacroix-Buchet, and M. Bouix, “Cell growth and resistance of Lactococcus lactis subsp. lactis TOMSC161 following freezing, drying and freeze-dried storage are differentially affected by fermentation conditions,” Journal of Applied Microbiology, vol. 117, no. 3, pp. 729–740, 2014. [Online]. Available: http://dx.doi.org/10.1111/jam.12577

[11] A. a. Yao, C. Dortu, M. Egounlety, C. Pinto, V. a. Edward, M. Huch, C. M. a. P. Franz, W. Holzapfel, S. Mbugua, M. Mengu, and P. Thonart, “Production of freeze-dried lactic acid bacteria starter culture for cassava fermentation into gari,” African Journal of Biotechnology, vol. 8, no. 19, pp. 4996–5004, 2009.

[12] X. C. Meng, C. Stanton, G. F. Fitzgerald, C. Daly, and R. P. Ross, “Anhydrobiotics: The challenges of drying probiotic cultures,” Food Chemistry, vol. 106, no. 4 SPEC. ISS., pp. 1406–1416, 2008. [Online]. Available: http://dx.doi.org/10.1016/j.foodchem.2007.04.076 195, 196, 202, 206,

[13] M. R. Armando, M. A. Galvagno, C. A. Dogi, P. Cerrutti, A. M. Dalcero, and L. R. Cavaglieri, “Statistical optimization of culture conditions for biomass production of probiotic gut-borne Saccharomyces cerevisiae strain able to reduce fumonisin B1,” Journal of Applied Microbiology, vol. 114, no. 5, pp. 1338–1346, 2013. [Online]. Available: http://dx.doi.org/10.1111/jam.12144

[14] P. M. Doran, Principios de Ingeniería de los Bioprocesos. Zaragoza: Acribia, 1998.

[15] A. S. Carvalho, J. Silva, P. Ho, P. Teixeira, F. X. Malcata, and P. Gibbs, “Relevant factors for the preparation of freeze-dried lactic acid bacteria,” International Dairy Journal, vol. 14, no. 10, pp. 835–847, 2004. [Online]. Available: http://dx.doi.org/10.1016/j.idairyj.2004.02.001

[16] C. Santivarangkna, U. Kulozik, and P. Foerst, “Inactivation mechanisms of lactic acid starter cultures preserved by drying processes,” Journal of Applied Microbiology, vol. 105, no. 1, pp. 1–13, 2008. [Online]. Available: http://dx.doi.org/10.1111/j.1365-2672.2008.03744.x

[17] E. J. Aguirre-Ezkauriatza, “Production of freeze dried protein and Lactobacillus casei probiotic,” Revista Mexicana De Ingenieria Quimica, vol. 8, no. 1, pp. 67–76, 2009.

[18] L. Wang, X. Yu, H. Xu, Z. P. Aguilar, and H. Wei, “Effect of skim milk coated inulin-alginate encapsulation beads on viability and gene expression of Lactobacillus plantarum during freeze-drying,” LWT - Food Science and Technology, vol. 68, pp. 8–13, 2016. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2015.12.001

[19] L. Montes, “Efecto de la microencapsulación con agentes prebióticos sobre la viabilidad de microorganismos probióticos (Lactobacillus casei ATCC 393 y Lactobacillus rhamnosus ATCC 9469),” Ph.D. dissertation, Universidad Nacional de Colombia, 2013. [Online]. Available: http: //www.bdigital.unal.edu.co/9473/1/01107466.2013.pdf

[20] R. B. Sneyder, G. I. Giraldo, and L. M. Montes, “Encapsulación De Alimentos Probióticos Mediante Liofilización En Presencia De Prebióticos,” Informacion Tecnologica, vol. 27, no. 6, pp. 135–144, 2016.

[21] J. M. Ramírez Monsalve, “Optimización experimental del proceso de liofilización de estragón ruso (Artemisia drancunculus L),” p. 57, 2014. [Online]. Available: http://www.bdigital.unal.edu.co/48966/

[22] C. Santivarangkna, M. Aschenbrenner, U. Kulozik, and P. Foerst, “Role of Glassy State on Stabilities of Freeze-Dried Probiotics,” Journal of Food Science, vol. 76, no. 8, pp. 152–157, 2011. [Online]. Available: http://dx.doi.org/10.1111/j.1750-3841.2011.02347.x

[23] C. A. Morgan, N. Herman, P. A. White, and G. Vesey, “Preservation of micro-organisms by drying; A review,” Journal of Microbiological Methods, vol. 66, no. 2, pp. 183–193, 2006. [Online]. Available: http://dx.doi.org/10.1016/j.mimet.2006.02.017

[24] P. Gong, L. Zhang, X. Han, N. Shigwedha, W. Song, H. Yi, M. Du, and C. Cao, “Injury Mechanisms of Lactic Acid Bacteria Starter Cultures During Spray Drying: A Review,” Drying Technology, vol. 32, no. 7, pp. 793–800, 2014. [Online]. Available: http://www.tandfonline.com/doi/abs/ 10.1080/07373937.2013.860458

[25] A. Ferreira, S. Huang, Í. Perrone, P. Schuck, G. Jan, and A. Carvalho, “Tracking Amazonian cheese microbial diversity: Development of an original, sustainable, and robust starter by freeze drying/spray drying,” Journal of Dairy Science, pp. 6997–7006, 2017. [Online]. Available: http://linkinghub.elsevier.com/retrieve/pii/S0022030217306835

[26] C. Santivarangkna, B. Higl, and P. Foerst, “Protection mechanisms of sugars during different stages of preparation process of dried lactic acid starter cultures,” Food Microbiology, vol. 25, no. 3, pp. 429–441, 2008. [Online]. Available: http://dx.doi.org/10.1016/j.fm.2007.12.004

[27] M. Teijeiro, P. F. Pérez, G. L. De Antoni, and M. A. Golowczyc, “Suitability of kefir powder production using spray drying,” Food Research International, vol. 112, no. June, pp. 169–174, 2018. [Online]. Available: https://doi.org/10.1016/j.foodres.2018.06.023

[28] K. Masters, Spray Drying Handbook, 5th ed., Longman Scientific & Technical, Ed., 1991.

[29] M. Y. Vera, “Metodología de diseño simultaneo de proceso y control aplicada a un secado por atomización multiproducto para sustancias químicas naturales,” Ph.D. dissertation, 2012.

[30] D. T. Tan, P. E. Poh, and S. K. Chin, “Microorganism preservation by convective air-drying—A review,” Drying Technology, vol. 36, no. 7, pp. 764–779, 2018. [Online]. Available: http://dx.doi.org/10.1080/07373937. 2017.1354876

[31] S. Salar-Behzadi, S. Wu, S. Toegel, M. Hofrichter, I. Altenburger, F. M. Unger, M. Wirth, and H. Viernstein, “Impact of heat treatment and spray drying on cellular properties and culturability of Bifidobacterium bifidum BB-12,” Food Research International, vol. 54, no. 1, pp. 93–101, 2013. [Online]. Available: http://dx.doi.org/10.1016/j.foodres.2013.05.024

[32] J. Antonio, C. Arias, L. Felipe, H. Guti, and L. Alberto, Revisiones sistemáticas de la literatura científica, 2016.

[33] Scimago Lab, “Scimago Journal & Country Rank,” 2018. [Online]. Available: https://www.scimagojr.com

[34] M. Jantzen, A. Göpel, and C. Beermann, “Direct spray drying and microencapsulation of probiotic Lactobacillus reuteri from slurry fermentation with whey,” Journal of Applied Microbiology, vol. 115, no. 4, pp. 1029–1036, 2013. [Online]. Available: http://dx.doi.org/10.1111/jam.12293

[35] S. Huang, C. Cauty, A. Dolivet, Y. Le Loir, X. D. Chen, P. Schuck, G. Jan, and R. Jeantet, “Double use of highly concentrated sweet whey to improve the biomass production and viability of spray-dried probiotic bacteria,” Journal of Functional Foods, vol. 23, pp. 453–463, 2016. [Online]. Available: http://dx.doi.org/10.1016/j.jff.2016.02.050

[36] P. Bustos and R. Bórquez, “Influence of Osmotic Stress and Encapsulating Materials on the Stability of Autochthonous Lactobacillus plantarum after Spray Drying,” Drying Technology, vol. 31, no. 1, pp. 57–66, 2013. [Online]. Available: http://dx.doi.org/10.1080/07373937.2012.717325

[37] K. B. Guergoletto, M. Busanello, and S. Garcia, “Influence of carrier agents on the survival of Lactobacillus reuteri LR92 and the physicochemical properties of fermented juçara pulp produced by spray drying,” LWT - Food Science and Technology, vol. 80, pp. 321–327, 2017. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2017.02.038

[38] W. Lapsiri, B. Bhandari, and P. Wanchaitanawong, “Stability and Probiotic Properties of Lactobacillus plantarum Spray-Dried with Protein and Other Protectants,” Drying Technology, vol. 31, no. 13-14, pp. 1723–1733, 2013. [Online]. Available: http://dx.doi.org/10.1080/07373937.2013.775658

[39] W. Savedboworn and P. Wanchaitanawong, “Viability and probiotic properties of Lactobacillus plantarum TISTR 2075 in spray-dried fermented cereal extracts,” Maejo International Journal of Science and Technology, vol. 9, no. 3, pp. 382–393, 2015. [Online]. Available: http://dx.doi.org/10.14456/mijst.2015.29

[40] W. Lapsiri, B. Bhandari, and P. Wanchaitanawong, “Viability of Lactobacillus plantarum TISTR 2075 in Different Protectants during Spray Drying and Storage,” Drying Technology, vol. 30, no. 13, pp. 1407–1412, 2012. [Online]. Available: http://dx.doi.org/10.1080/07373937.2012.684226

[41] P. Mishra, S. Mishra, and C. L. Mahanta, “Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder,” Food and Bioproducts Processing, vol. 92, no. 3, pp. 252–258, 2014. [Online]. Available: http://dx.doi.org/10.1016/j.fbp.2013.08.003

[42] D. Seth, H. N. Mishra, and S. C. Deka, “Effect of spray drying process conditions on bacteria survival and acetaldehyde retention in sweetened yoghurt powder: An optimization study,” Journal of Food Process Engineering, vol. 40, no. 3, 2017. [Online]. Available: http://dx.doi.org/10.1111/jfpe.12487

[43] P. Burns, F. Molinari, A. Beccaria, R. Páez, C. Meinardi, J. Reinheimer, and G. Vinderola, “Suitability of buttermilk for fermentation with Lactobacillus helveticus and production of a functional peptide-enriched powder by spraydrying,” Journal of Applied Microbiology, vol. 109, no. 4, pp. 1370–1378, 2010. [Online]. Available: http://dx.doi.org/10.1111/j.1365-2672.2010.04761.x

[44] T. Petreska-Ivanovska, L. Petrushevska-Tozi, A. Grozdanov, R. Petkovska, J. Hadjieva, E. Popovski, T. Stafilov, and K. Mladenovska, “From optimization of synbiotic microparticles prepared by spray-drying to development of new functional carrot juice,” Chemical Industry and Chemical Engineering Quarterly, vol. 20, no. 4, pp. 549–564, 2014. [Online]. Available: http://www.doiserbia.nb.rs/Article.aspx?ID=1451-93721300036P

[45] L. Lavari, R. Ianniello, R. Páez, T. Zotta, A. Cuatrin, J. Reinheimer, E. Parente, and G. Vinderola, “Growth of Lactobacillus rhamnosus 64 in whey permeate and study of the effect of mild stresses on survival to spray drying,” LWT - Food Science and Technology, vol. 63, no. 1, pp. 322–330, 2015. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2015.03.066

[46] P. Chaikham, V. Kemsawasd, and P. Seesuriyachan, “Spray drying probiotics along with maoluang juice plus Tiliacora triandra gum for exposure to the in vitro gastrointestinal environments,” LWT - Food Science and Technology, vol. 78, pp. 31–40, 2017. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2016.12.013

[47] G. Quintana, E. Gerbino, and A. Gómez-Zavaglia, “Valorization of okara oil for the encapsulation of Lactobacillus plantarum,” Food Research International, vol. 106, no. October 2017, pp. 81–89, 2018. [Online]. Available: https://doi.org/10.1016/j.foodres.2017.12.053

[48] S. Pispan, C. Hewitt, and A. Stapley, “Comparison of cell survival rates of E. coli K12 and L. acidophilus undergoing spray drying,” Food and Bioproducts, no. July 2012, pp. 362–369, 2013. [Online]. Available: http://dx.doi.org/10.1016/j.fbp.2013.01.005

[49] G. Broeckx, D. Vandenheuvel, T. Henkens, S. Kiekens, M. F. L. van den Broek, S. Lebeer, and F. Kiekens, “Enhancing the viability of Lactobacillus rhamnosus GG after spray drying and during storage,” International Journal of Pharmaceutics, vol. 534, no. 1-2, pp. 35–41, 2017. [Online]. Available: http://dx.doi.org/10.1016/j.ijpharm.2017.09.075

[50] M. A. Golowczyc, J. Silva, P. Teixeira, G. L. D. Antoni, and A. G. Abraham, “Cellular injuries of spray-dried Lactobacillus spp . isolated from kefir and their impact on probiotic properties,” International Journal of Food Microbiology, vol. 144, no. 3, pp. 556–560, 2011. [Online]. Available: http://dx.doi.org/10.1016/j.ijfoodmicro.2010.11.005

[51] K. B. P. K. Reddy, A. N. Madhu, and S. G. Prapulla, “Comparative survival and evaluation of functional probiotic properties of spray-dried lactic acid bacteria: ORIGINAL RESEARCH,” International Journal of Dairy Technology, vol. 62, no. 2, pp. 240–248, 2009. [Online]. Available: http://dx.doi.org/10.1111/j.1471-0307.2009.00480.x

[52] M. I. Santos, C. Araujo-Andrade, E. E. Tymczyszyn, and A. Gómez-Zavaglia, “Determination of amorphous/rubbery states in freeze-dried prebiotic sugars using a combined approach of near-infrared spectroscopy and multivariate analysis,” Food Research International, vol. 64, pp. 514–519, 2014. [Online]. Available: http://dx.doi.org/10.1016/j.foodres.2014.07.040

[53] M. I. Santos, “Galacto-oligosacáridos y Lactulosa como Protectores en la Preservación de Bacterias Lácticas. Utilización de Métodos Espectroscópicos y de Análisis Multivariante para la Determinación de su Eficiencia,” 2015. [Online]. Available: http://digibug.ugr.es/bitstream/10481/931/1/16080889. pdf

[54] M. I. Santos, E. Gerbino, C. Araujo-Andrade, E. E. Tymczyszyn, and A. G??mez-Zavaglia, “Stability of freeze-dried Lactobacillus delbrueckii subsp. bulgaricus in the presence of galacto-oligosaccharides and lactulose as determined by near infrared spectroscopy,” Food Research International, vol. 59, pp. 53–60, 2014. [Online]. Available: http://dx.doi.org/10.1016/j. foodres.2014.01.054

[55] J. Perdana, M. B. Fox, C. Siwei, R. M. Boom, and M. A. Schutyser, “Interactions between formulation ans spray drying conditions related to survival of Lactobacillus plantarum WCFS1,” Food Research International, vol. 56, pp. 9–17, 2014. [Online]. Available: http://dx.doi.org/10.1016/j. foodres.2013.12.007

[56] Z. Zhu, C. Luan, H. Zhang, L. Zhang, and Y. Hao, “Effects of spray drying on Lactobacillus plantarum BM-1 viability, resistance to simulated gastrointestinal digestion, and storage stability,” Drying Technology, vol. 34, no. 2, pp. 177–184, 2016. [Online]. Available: http://www.tandfonline.com/doi/full/10.1080/07373937.2015.1021009

[57] E. C. Ilha, T. da Silva, J. G. Lorenz, G. de Oliveira Rocha, and E. S. Sant’Anna, “Lactobacillus paracasei isolated from grape sourdough: acid, bile, salt, and heat tolerance after spray drying with skim milk and cheese whey,” European Food Research and Technology, vol. 240, no. 5, pp. 977–984, 2015. [Online]. Available: http://dx.doi.org/10.1007/s00217-014-2402-x

[58] M. Bustamante, M. Villarroel, M. Rubilar, and C. Shene, “Lactobacillus acidophilus La-05 encapsulated by spray drying: Effect of mucilage and protein from flaxseed (Linum usitatissimum L.),” LWT - Food Science and Technology, vol. 62, pp. 1162–1168, 2014. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2015.02.017

[59] L. K. Liao, X. Y. Wei, X. Gong, J. H. Li, T. Huang, and T. Xiong, “Microencapsulation of Lactobacillus casei LK-1 by spray drying related to its stability and invitro digestion,” LWT - Food Science and Technology, vol. 82, pp. 82–89, 2017. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2017.03.065

[60] S. Huang and X. D. Chen, “Significant effect of Ca2+ on improving the heat resistance of lactic acid bacteria,” FEMS Microbiology Letters, vol. 344, no. 1, pp. 31–38, 2013. [Online]. Available: http://dx.doi.org/10.1111/ 1574-6968.12151

[61] S. Khem, D. M. Small, and B. K. May, “The behaviour of whey protein isolate in protecting Lactobacillus plantarum,” Food Chemistry, vol. 190, pp. 717–723, 2016. [Online]. Available: http://dx.doi.org/10.1016/j.foodchem. 2015.06.020

[62] C. Li, Y. Wang, Q. Li, and N. Xu, “Yogurt Starter Obtained from Lactobacillus plantarum by Spray Drying,” Drying Technology, vol. 30, no. 15, pp. 1698–1706, 2012. [Online]. Available: http://dx.doi.org/10.1080/ 07373937.2012.714824

[63] C. J. Cai, B. Thaler, J. W. Liu, J. J. Wang, and S. Y. Qiao, “Optimization of spray-drying workflow as a method for preparing concentrated cultures of Lactobacillus fermentum,” pp. 2769–2774, 2012. [Online]. Available: http://dx.doi.org/10.3923/javaa.2012.2769.2774

[64] M. L. Pérez-Chabela, R. Lara-Labastida, E. Rodriguez-Huezo, and A. Totosaus, “Effect of Spray Drying Encapsulation of Thermotolerant Lactic Acid Bacteria on Meat Batters Properties,” Food and Bioprocess Technology, vol. 6, no. 6, pp. 1505–1515, 2013. [Online]. Available: http://dx.doi.org/10.1007/s11947-012-0865-y

[65] K. Anekella and V. Orsat, “Optimization of microencapsulation of probiotics in raspberry juice by spray drying,” LWT - Food Science and Technology, vol. 50, no. 1, pp. 17–24, 2013. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2012.08.003

[66] D. Y. Ying, M. C. Phoon, L. Sanguansri, R. Weerakkody, I. Burgar, and M. A. Augustin, “Microencapsulated Lactobacillus rhamnosus GG Powders: Relationship of Powder Physical Properties to Probiotic Survival during Storage,” Journal of Food Science, vol. 75, no. 9, 2010. [Online]. Available: http://dx.doi.org/10.1111/j.1750-3841.2010.01838.x

[67] E. O. Sunny-Roberts and D. Knorr, “Evaluation of the response of Lactobacillus rhamnosus VTT E-97800 to sucrose-induced osmotic stress,” Food Microbiology, vol. 25, no. 1, pp. 183–189, 2008. [Online]. Available: http://dx.doi.org/10.1016/j.fm.2007.05.003

[68] J. Barbosa, S. Borges, and P. Teixeira, “Influence of sub-lethal stresses on the survival of lactic acid bacteria after spray-drying in orange juice,” Food Microbiology, vol. 52, pp. 77–83, 2015. [Online]. Available: http://dx.doi.org/10.1016/j.fm.2015.06.010

[69] Å. S. Bergenholtz, P. Wessman, A. Wuttke, and S. Håkansson, “A case study on stress preconditioning of a Lactobacillus strain prior to freeze-drying,” Cryobiology, vol. 64, no. 3, pp. 152–159, 2012. [Online]. Available: http://dx.doi.org/10.1016/j.cryobiol.2012.01.002

[70] Z. Shokri, M. R. Fazeli, M. Ardjmand, S. M. Mousavi, and K. Gilani, “Factors affecting viability of Bifidobacterium bifidum during spray drying,” DARU, Journal of Pharmaceutical Sciences, vol. 23, no. 1, 2015. [Online]. Available: http://dx.doi.org/10.1186/s40199-014-0088-z

[71] Y. Zhang, J. Lin, and Q. Zhong, “Effects of media, heat adaptation, and outlet temperature on the survival of Lactobacillus salivarius NRRL B-30514 after spray drying and subsequent storage,” LWT - Food Science and Technology, vol. 74, pp. 441–447, 2016. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2016.08.008

[72] A. Mishra and K. A. Athmaselvi, “Stress tolerance and physicochemical properties of encapsulation processes for Lactobacillus rhamnosus in pomegranate (Punica granatum L.) fruit juice,” Food Science and Biotechnology, vol. 25, no. 1, pp. 125–129, 2016. [Online]. Available: http://dx.doi.org/10.1007/s10068-016-0019-5

[73] C. S. Ranadheera, C. A. Evans, M. C. Adams, and S. K. Baines, “Microencapsulation of Lactobacillus acidophilus LA-5, Bifidobacterium animalis subsp. lactis BB-12 and Propionibacterium jensenii 702 by spray drying in goat’s milk,” Small Ruminant Research, vol. 123, no. 1, pp. 155–159, 2015. [Online]. Available: http://dx.doi.org/10.1016/j.smallrumres. 2014.10.012

[74] B. Koc, M. S. Yilmazer, P. Balkir, and F. K. Ertekin, “Spray drying of yogurt: Optimization of process conditions for improving viability and other quality attributes,” Drying Technology, vol. 28, no. 4, pp. 495–507, 2010. [Online]. Available: http://dx.doi.org/10.1080/07373931003613809

[75] E. E. Tymczyszyn, R. Díaz, A. Pataro, N. Sandonato, A. Gómez-Zavaglia, and E. A. Disalvo, “Critical water activity for the preservation of Lactobacillus bulgaricus by vacuum drying,” International Journal of Food Microbiology, vol. 128, no. 2, pp. 342–347, 2008. [Online]. Available: http://dx.doi.org/10.1016/j.ijfoodmicro.2008.09.009

[76] J. Agudelo, A. Cano, C. González-Martínez, and A. Chiralt, “Disaccharide incorporation to improve survival during storage of spray dried Lactobacillus rhamnosus in whey protein-maltodextrin carriers,” Journal of Functional Foods, vol. 37, pp. 416–426, 2017. [Online]. Available: http://dx.doi.org/10. 1016/j.jff2017.08.014

[77] D. Dimitrellou, P. Kandylis, T. Petrović, S. Dimitrijević-Branković, S. Lević, V. Nedović, and Y. Kourkoutas, “Survival of spray dried microencapsulated Lactobacillus casei ATCC 393 in simulated gastrointestinal conditions and fermented milk,” LWT - Food Science and Technology, vol. 71, pp. 169–174, 2016. [Online]. Available: http://dx.doi.org/10.1016/j.lwt.2016.03.007

[78] S. Khem, V. Bansal, D. M. Small, and B. K. May, “Comparative influence of pH and heat on whey protein isolate in protecting Lactobacillus plantarum A17 during spray drying,” Food Hydrocolloids, vol. 54, pp. 162–169, 2016. [Online]. Available: http://dx.doi.org/10.1016/j.foodhyd.2015.09.029

[79] N. Sosa, E. Gerbino, M. A. Golowczyc, C. Schebor, A. Gómez-Zavaglia, and E. E. Tymczyszyn, “Effect of galacto-oligosaccharides: Maltodextrin matrices on the recovery of Lactobacillus plantarum after spray-drying,” Frontiers in Microbiology, vol. 7, no. MAY, pp. 1–8, 2016. [Online]. Available: http://dx.doi.org/10.3389/fmicb.2016.00584

[80] C. Soukoulis, S. Behboudi-Jobbehdar, L. Yonekura, C. Parmenter, and I. Fisk, “Impact of Milk Protein Type on the Viability and Storage Stability of Microencapsulated Lactobacillus acidophilus NCIMB 701748 Using Spray Drying,” Food and Bioprocess Technology, vol. 7, no. 5, pp. 1255–1268, 2014. [Online]. Available: http://dx.doi.org/10.1007/s11947-013-1120-x

[81] G. Maciel, K. Chaves, C. Grosso, and M. Gigante, “Microencapsulation of Lactobacillus acidophilus La-5 by spray-drying using sweet whey and skim milk as encapsulating materials,” Journal of Dairy Science, vol. 97, no. 4, pp. 1991–1998, 2014. [Online]. Available: http://linkinghub.elsevier. com/retrieve/pii/S0022030214000964

[82] L. Yonekura, H. Sun, C. Soukoulis, and I. Fisk, “Microencapsulation of Lactobacillus acidophilus NCIMB 701748 in matrices containing soluble fibre by spray drying: Technological characterization, storage stability and survival after in vitro digestion,” Journal of Functional Foods, vol. 6, no. 1, pp. 205– 214, 2014. [Online]. Available: http://dx.doi.org/10.1016/j.jff.2013.10.008

[83] Z. Hernández-López, E. Rangel-Vargas, J. Castro-Rosas, C. A. GómezAldapa, A. Cadena-Ramírez, O. A. Acevedo-Sandoval, A. J. GordilloMartínez, and R. N. Falfán-Cortés, “Optimization of a spray-drying process for the production of maximally viable microencapsulated Lactobacillus pentosus using a mixture of starch-pulque as wall material,” Lwt, vol. 95, no. April, pp. 216–222, 2018. [Online]. Available: https: //doi.org/10.1016/j.lwt.2018.04.075

[84] P. Gong, L. Zhang, J. Zhang, X. Han, H. Yi, W. Di, and S. Chen, “Sampling method for studying the activity of lactic acid bacteria during spray drying,” Drying Technology, vol. 36, no. 10, pp. 1–7, 2018. [Online]. Available: https://doi.org/10.1080/07373937.2017.1396226

[85] J. Barbosa, T. R. S. Brandão, and P. Teixeira, “Spray drying conditions for orange juice incorporated with lactic acid bacteria,” International Journal of Food Science & Technology, vol. 52, no. 9, pp. 1951–1958, 2017. [Online]. Available: http://doi.wiley.com/10.1111/ijfs.13472

[86] G. H. Peralta, C. V. Bergamini, G. Audero, R. Páez, I. V. Wolf, M. C. Perotti, and E. R. Hynes, “Spray-dried adjunct cultures of autochthonous non-starter lactic acid bacteria,” International Journal of Food Microbiology, vol. 255, no. May, pp. 17–24, 2017. [Online]. Available: http://dx.doi.org/10.1016/j.ijfoodmicro.2017.05.014

[87] V. Reyes, A. Chotiko, A. Chouljenko, and S. Sathivel, “Viability of Lactobacillus acidophilus NRRL B-4495 encapsulated with high maize starch, maltodextrin, and gum arabic,” Lwt, vol. 96, no. June, pp. 642–647, 2018. [Online]. Available: https://doi.org/10.1016/j.lwt.2018.06.017

[88] M. Archacka, W. Białas, R. Dembczyński, A. Olejnik, A. Sip, D. Szymanowska, E. Celińska, T. Jankowski, A. Olejnik, and M. Rogodzińska, “Method of preservation and type of protective agent strongly influence probiotic properties of Lactococcus lactis: A complete process of probiotic preparation manufacture and use,” Food Chemistry, vol. 274, no. September, pp. 733–742, 2019. [Online]. Available: http://dx.doi.org/10.1016/j.foodchem.2018.09.033