Estudio experimental y simulación numérica de las medidas de microdureza en aleaciones Al-Fe en diferentes velocidades de barridos con rayo láser

Main Article Content

Keywords

Refundición superficial con láser, características microestructurales, FEG-EDS, microdureza, modelamento de la indentación, FEM

Resumen

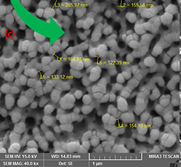

En la aleación de Al-2,0 % Fe se realizó el tratamiento de refundición superficial con láser (RSL) para investigar las muestras con capas tratadas y no tratadas con diferentes velocidades de barrido con rayos láser, entre ellas, 80, 100 y 120 mm/s, respectivamente. En este artículo se presentaron y discutieron las características microestructurales utilizando las técnicas FEG y EDS. Además se llevaron a cabo experimentos y de simulación numérica por MEF de las indentaciones piramidales de la superficie tratados y no tratados con LSR. En la sección transversal de la muestra tratada con barrido lento de rayos láser y, específicamente en la geometría de la piscina fundida, la microestructura presentaba características de crecimiento columnar y también muestra muchas nanoporosidades. Sin embargo, con barrido de rayo láser alto, la microestructura muestra una disposición celular con grano fino, no obstante, la concentración de nanoporosidades y el tamaño de la geometría de la piscina fundida se redujeron ligeramente. Además, las medidas de la microdureza en la zona tratada con RSL aumentó ligeramente en función del aumento de la velocidad del rayo láser, pero la microdureza fue mucho mayor que en la muestra no tratada. También, se calculó con éxito el modelaje de la indentación de la microdureza con el software COMSOL de la muestra tratada por RSL y no tratada por el método de elementos finitos. Por lo tanto, se encontró un buen acuerdo entre los datos experimentales y los simulados.

Descargas

Referencias

https://doi.org/10.1016/j.jallcom.2017.01.131

[2] T. Zienert and O. Fabrichnaya, “Experimental investigation and thermodynamic assessment of the al-fe system,” Journal of Alloys and Compounds, vol. 743, pp. 795 – 811, 2018. [Online]. Available: https://doi.org/10.1016/j.jallcom.2018.01.316

[3] K. Han, I. Ohnuma, and R. Kainuma, “Experimental determination of phase equilibria of al-rich portion in the al–fe binary system,” Journal of Alloys and Compounds, vol. 668, pp. 97 – 106, 2016. [Online]. Available: https://doi.org/10.1016/j.jallcom.2016.01.215

[4] S. Mukherjee, S. Chakraborty, R. Galun, Y. Estrin, and I. Manna, “Transport phenomena in conduction mode laser beam welding of fe–al dissimilar couple with ta diffusion barrier,” International Journal of Heat and Mass Transfer, vol. 53, no. 23, pp. 5274 – 5282, 2010. [Online]. Available: https://doi.org/10.1016/j.ijheatmasstransfer.2010.07.032

[5] P. R. Goulart, V. B. Lazarine, C. V. Leal, J. E. Spinelli, N. Cheung, and A. Garcia, “Investigation of intermetallics in hypoeutectic al–fe alloys by dissolution of the al matrix,” Intermetallics, vol. 17, no. 9, pp. 753 – 761, 2009. [Online]. Available: https://doi.org/10.1016/j.intermet.2009.03.003

[6] J. Swadener, E. George, and G. Pharr, “The correlation of the indentation size effect measured with indenters of various shapes,” Journal of the Mechanics and Physics of Solids, vol. 50, no. 4, pp. 681 – 694, 2002.

[Online]. Available: https://doi.org/10.1016/S0022-5096(01)00103-X

[7] J. Chen and S. Bull, “The investigation of creep of electroplated sn and ni–sn coating on copper at room temperature by nanoindentation,” Surface and Coatings Technology, vol. 203, no. 12, pp. 1609 – 1617, 2009. [Online]. Available: https://doi.org/10.1016/j.surfcoat.2008.12.007

[8] J. Bressan, A. Tramontin, and C. Rosa, “Modeling of nanoindentation of bulk and thin film by finite element method,” Wear, vol. 258, no. 1, pp. 115 – 122, 2005, second International Conference on Erosive and Abrasive Wear. [Online]. Available: https://doi.org/10.1016/j.wear.2004.05.021

[9] M. Fivel, L. Tabourot, E. Rauch, and E. Canova, “Identification through mesoscopic simulations of macroscopic parameters of physically based constitutive equations for the plastic behaviour of fcc single crystats,” J. Phys. IV France, vol. 08, pp. 151–158, 1998. [Online]. Available: https://doi.org/10.1051/jp4:1998819

[10] A. Abbo, “Finite element algorithms for elastoplasticity and consolidation,” Ph.D. dissertation, University of Newcastle, 2005.

[11] M. Kot, W. Rakowski, L. Major, and J. Lackner, “Load-bearing capacity of coating–substrate systems obtained from spherical indentation tests,” Materials & Design, vol. 46, pp. 751 – 757, 2013. [Online]. Available: https://doi.org/10.1016/j.matdes.2012.11.026

[12] A. S. Alaboodi and Z. Hussain, “Finite element modeling of nanoindentation technique to characterize thin film coatings,” Journal of King Saud University - Engineering Sciences, vol. 31, no. 1, pp. 61 – 69, 2019. [Online]. Available: https://doi.org/10.1016/j.jksues.2017.02.001

[13] P. S. Pandure, V. S. Jatti, and T. Singh, “Finite element simulation of nano-indentation of dlc coated hss substrate,” Procedia Materials Science, vol. 6, pp. 1619 – 1624, 2014, 3rd International Conference on Materials Processing and Characterisation (ICMPC 2014). [Online]. Available: https://doi.org/10.1016/j.mspro.2014.07.145

[14] S. M. Holzer and Z. Yosibash, “The p-version of the finite element method in incremental elasto-plastic analysis,” International Journal for Numerical Methods in Engineering, vol. 39, no. 11, pp. 1859–1878,

1996. [Online]. Available: 10.1002/(SICI)1097-0207(19960615)39:11<1859::AID-NME932>3.0.CO;2-7 62, 65

[15] K. Krabbenhøft, “Basic computational plasticity,” University of Denmark, 2002, department of Civil Engineering Technical. [Online]. Available: http://homes.civil.aau.dk/lda/continuum/plast.pdf

[16] D. J. Celentano, B. Guelorget, M. François, M. A. Cruchaga, and A. Slimane, “Numerical simulation and experimental validation of the microindentation test applied to bulk elastoplastic materials,” Modelling and Simulation in Materials Science and Engineering, vol. 20, no. 4, p. 045007, apr 2012. [Online]. Available: https://doi.org/10.1088/0965-0393/20/4/045007

[17] M. Pariona and T. Micene, “The alumina film nanomorphology formed to improve the corrosion resistance of al-2.0 wt% fe alloy as result of the laser surface melting technique,” Applied Advances in Chemical Engineering and Science, vol. 7, pp. 10–22, 2017. [Online]. Available: https://doi.org/10.4236/aces.2017.71002

[18] P. Goulart, “Characterization of the solidification microstructure of al-fe alloys and correlation in mechanical properties,” Ph.D. dissertation, Universidade Estadual de Campinas (UNICAMP), 2010.

[19] M. M. Pariona, V. Teleginski, K. dos Santos, S. Machado, A. J. Zara, N. K. Zurba, and R. Riva, “Yb-fiber laser beam effects on the surface modification of al–fe aerospace alloy obtaining weld filet structures, low fine porosity and corrosion resistance,” Surface and Coatings Technology, vol. 206, no. 8, pp. 2293 – 2301, 2012. [Online]. Available: https://doi.org/10.1016/j.surfcoat.2011.10.007

[20] M. M. Pariona, A. F. Taques, and L. A. Woiciechowski, “The marangoni effect on microstructure properties and morphology of laser-treated al-fe alloy with single track by fem: Varying the laser beam velocity,” International Journal of Heat and Mass Transfer, vol. 119, pp. 10 – 19, 2018. [Online]. Available: https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.097

[21] J. Gallardo, L. Soria, and E. Herrera, “Investigation of service failures in automobile shock absorbers,” Engineering Failure Analysis, vol. 14, no. 2, pp. 355 – 363, 2007, papers presented at the 22nd meeting of the

Spanish Fracture Group (Almargro, Spain, March 2005). [Online]. Available: https://doi.org/10.1016/j.engfailanal.2006.02.006