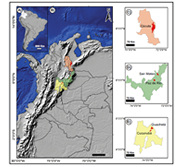

Modelo predictivo del índice de anisotropía del semicoque a partir de las propiedades de los carbones de la Cordillera Oriental de Colombia

Main Article Content

Keywords

Carbones, coeficiente de anisotropía del coque, semicoque, componentes texturales, Cordillera Oriental de Colombia

Resumen

En esta investigación se desarrolló un modelo teórico para la determinación del Cociente de Anisotropía del Coque (CAQ) del semicoque a partir de las propiedades de su carbón precursor. El CAQ permite definir la resistencia y la reactividad del semicoque en el alto horno. Usando material residual de las pruebas de fluidez se realizó un análisis textural para determinar el CAQ real sobre 36 muestras de semicoque. Las principales texturas observadas para los carbones bituminosos fueron: isotrópicas y circulares para los de alta volatilidad (HVB); cintas lenticulares y finas para los de media volatilidad (MVB); y cintas medias y gruesas para los de baja volatilidad (LVB). El CAQ varió en un rango de 1 a 11. Análisis de componentes principales (PCA) y regresión múltiple permitieron reconocer la importancia de ciertas propiedades del carbón para determinar el CAQ. El análisis estadístico sugirió que el CAQ puede predecirse mejor a partir de la fluidez,

la materia volátil y el Ro de los carbones precursores. Este modelo fue validado a través de la comparación con datos reales de carbones de Polonia. Este trabajo proporciona un medio de control de calidad que podría

implementarse en la producción de coque colombiano.

Descargas

Referencias

[2] B. Kwiecińska and H. Petersen, “Graphite, semi-graphite, natural coke, and natural char classification–iccp system,” International Journal of Coal Geology, vol. 57, no. 2, pp. 99 – 116, 2004. https://doi.org/10.1016/j.coal.2003.09.003

[3] N. Choudhury, D. Mohanty, P. Boral, S. Kumar, and S. K. Hazra, “Microscopic evaluation of coal and coke for metallurgical usage,” Current Science, vol. 94, no. 1, pp. 74–81, 2008. http://www.jstor.org/stable/ 24102031

[4] I. Suárez-Ruiz and C. R. Ward, Chapter 2 - Basic Factors Controlling Coal Quality and Technological Behavior of Coal, I. Su’arez-Ruiz and J. C. Crelling, Eds. Burlington: Elsevier, 2008. https://doi.org/10.1016/B978-0-08-045051-3.00002-6

[5] T. Larry, Coal Geology. John Wiley and Sons Ltd, England, 2002.

[6] V. Gulyaev, V. Barskii, and A. Rudnitskii, “European quality requirements on blast-furnace coke,” Coke and Chemistry, vol. 55, no. 10, pp. 372–376, 2012. https://doi.org/10.3103/S1068364X12100043

[7] M. Dıez, R. Alvarez, and C. Barriocanal, “Coal for metallurgical coke production: predictions of coke quality and future requirements for cokemaking,” International Journal of Coal Geology, vol. 50, no. 1-4, pp. 389–412, 2002. https://doi.org/10.1016/S0166-5162(02)00123-4

[8] J. W. Patrick, M. J. Reynolds, and F. H. Shaw, “Development of optical anisotropy in vitrains during carbonization,” Fuel, vol. 52, no. 3, pp. 198–204, 1973. https://doi.org/10.1016/0016-2361(73)90079-3

[9] A. Moreland, J. W. Patrick, and A. Walker, “Optical anisotropy in cokes from high-rank coals,” Fuel, vol. 67, no. 5, pp. 730–732, 1988. https://doi.org/10.1016/0016-2361(88)90307-9

[10] A. Varma, “Influence of petrographical composition on coking behavior of inertinite-rich coals,” International journal of coal geology, vol. 30, no. 4, pp. 337–347, 1996. https://doi.org/10.1016/0166-5162(95)00053-4

[11] S. Pusz, B. Kwiecińska, A. Koszorek, M. Krzesińska, and B. Pilawa, “Relationships between the optical reflectance of coal blends and the microscopic characteristics of their cokes,” International Journal of Coal Geology, vol. 77, no. 3-4, pp. 356–362, 2009. https://doi.org/10.1016/j.coal. 2008.06.003

[12] K. Hiraki, H. Hayashizaki, Y. Yamazaki, T. Kanai, X. Zhang, M. Shoji, H. Aoki, T. Miura, and K. Fukuda, “The effect of changes in microscopic structures on coke strength in carbonization process,” ISIJ international, vol. 51, no. 4, pp. 538–543, 2011. https://doi.org/10.2355/isijinternational.51.538

[13] M. Piechaczek, A. Mianowski, and A. Sobolewski, “The original concept of description of the coke optical texture,” International journal of coal geology, vol. 139, pp. 184–190, 2015. https://doi.org/10.1016/j.coal.2014.07.002

[14] L. North, K. Blackmore, K. Nesbitt, and M. R. Mahoney, “Models of coke quality prediction and the relationships to input variables: a review,” Fuel, vol. 219, pp. 446–466, 2018. https://doi.org/10.1016/j.fuel.2018.01.062

[15] C. F. Diessel and E. Wolff-Fischer, “Coal and coke petrographic investigations into the fusibility of carboniferous and permian coking coals,” International journal of coal geology, vol. 9, no. 1, pp. 87–108, 1987. https://doi.org/10.1016/0166-5162(87)90066-8

[16] R. Sharma, P. Dash, P. Banerjee, and D. Kumar, “Effect of coke micro-textural and coal petrographic properties on coke strength characteristics,” ISIJ international, vol. 45, no. 12, pp. 1820–1827, 2005. https://doi.org/10.2355/isijinternational.45.1820

[17] J. C. Hower and W. G. Lloyd, “Petrographic observations of gieseler semi-cokes from high volatile bituminous coals,” Fuel, vol. 78, no. 4, pp. 445–451, 1999. https://doi.org/10.1016/S0016-2361(98)00170-7

[18] A. Guerrero, M. A. Diez, and A. G. Borrego, “Influence of charcoal fines on the thermoplastic properties of coking coals and the optical properties of the semicoke,” International Journal of Coal Geology, vol. 147, pp. 105–114, 2015. https://doi.org/10.1016/j.coal.2015.06.013

[19] A. G. Borrego and M. A. Diez, Petrografía del Coque metalúrgico. Incar, Ed. Oviedo, 2014.

[20] V. J. B. Bitencourt and S. R. Dillenburg, “Application of multivariate statistical techniques in alongshore differentiation of coastal barriers,” Marine Geology, vol. 419, p. 106077, 2020. https://doi.org/10.1016/j.margeo.2019.106077

[21] J. Davis, Statistics and Data Analysis in Geology, John Wiley and Sons, New York, 656, 2002.

[22] R Core Team, R: A Language and Environment for Statistical Computing, R Foundation for Statistical Computing, Vienna, Austria, 2017. https://www.R-project.org/

[23] S. Padoan, A. Zappi, T. Adam, D. Melucci, A. Gambaro, G. Formenton, O. Popovicheva, D.-L. Nguyen, J. Schnelle-Kreis, and R. Zimmermann, “Organic molecular markers and source contributions in a polluted municipality of north-east italy: Extended pca-pmf statistical approach,” Environmental Research, p. 109587, 2020. https://doi.org/10.1016/j.envres.2020.109587

[24] M. Mrówczyńska, J. Sztubecki, and A. Greinert, “Compression of results of geodetic displacement measurements using the pca method and neural networks,” Measurement, vol. 158, pp. 1–12, 2020. https://doi.org/10.1016/j.measurement.2020.107693

[25] S. Makvandi, G. Beaudoin, M. Beth McClenaghan, D. Quirt, and P. Ledru, “Pca of fe-oxides mla data as an advanced tool in provenance discrimination and indicator mineral exploration: Case study from bedrock and till from the kiggavik u deposits area (nunavut, canada),” Journal of Geochemical Exploration, vol. 197, pp. 199 – 211, 2019. https://doi.org/10.1016/j.gexplo.2018.11.013

[26] M. Kutner, J. Neter, C. Nachtsheim, and W. Wasserman, Applied Linear Statistical Model Richard D, 2004.

[27] C. L. Guatame and G. Sarmiento, “Interpretación del ambiente sedimentario de los carbones de la formación guaduas en el sinclinal checua-lenguazaque a partir del análisis petrográfico,” Geología Colombiana, vol. 29, pp. 41–57, 2004.

[28] L. J. M. Umaña, C. E. C. Gómez, and J. F. G. Casallas, “Análisis de microlitotipos en los carbones de la formación guaduas en el sinclinal de sueva, cundinamarca,” Geología Colombiana, vol. 31, pp. 11–26, 2006.

[29] J. S. Gómez-Neita, M. D. López-Carrasquilla, S. R. Manosalva-Sánchez, and W. E. Naranjo-Merchán, “Aportes a la determinación de paleoambientes, carbones del sinclinal checua-lenguazaque. colombia,” Ingeniería Investigación y Desarrollo, vol. 16, no. 2, pp. 32–42, 2016. https://doi.org/10.19053/1900771X.v16.n2.2016.5444

[30] J. S. Gómez-Neita, M. Costa-Pompeu, S. R. Manosalva-Sánchez, A. A. Evangelista-Nogueira, W. E. Naranjo-Merchán, and A. Matos de Lima, “Organic petrography of cretaceous coals in Colombia, Sutatausa-cucunuba region,” Bomgeam, vol. 3, 2019. http://doi.org/10.31419/ISSN.2594-942X. v62019i3a2JSGN

[31] O. P. Gómez Rojas, A. Blandón, C. Perea, and M. Mastalerz, “Petrographic characterization, variations in chemistry, and paleoenvironmental interpretation of colombian coals,” International Journal of Coal Geology, p. 103516, 2020. https://doi.org/10.1016/j.coal.2020.103516

[32] E. Díaz-Faes, C. Barriocanal, M. Diez, and R. Alvarez, “Applying tga parameters in coke quality prediction models,” Journal of analytical and applied pyrolysis, vol. 79, no. 1-2, pp. 154–160, 2007. https://doi.org/10.1016/j.jaap.2006.11.001

[33] Ł. Smędowski and M. Piechaczek, “Impact of weathering on coal properties and evolution of coke quality described by optical and mechanical parameters,” International Journal of Coal Geology, vol. 168, pp. 119–130, 2016. https://doi.org/10.1016/j.coal.2016.08.005

[34] X. Guo, Y. Tang, C. F. Eble, Y. Wang, and P. Li, “Study on petrographic characteristics of devolatilization char/coke related to coal rank and coal maceral,” International Journal of Coal Geology, p. 103504, 2020. https://doi.org/10.1016/j.coal.2020.103504

[35] Y. Yuan, Q. Qu, L. Chen, and M. Wu, “Modeling and optimization of coal blending and coking costs using coal petrography,” Information Sciences, vol. 522, pp. 49 – 68, 2020. https://doi.org/10.1016/j.ins.2020.02.072

[36] B. D. Flores, A. G. Borrego, M. A. Diez, G. L. da Silva, V. Zymla, A. C. Vilela, and E. Osório, “How coke optical texture became a relevant tool for understanding coal blending and coke quality,” Fuel Processing Technology, vol. 164, pp. 13–23, 2017. https://doi.org/10.1016/j.fuproc.2017.04.015

[37] S. Chehreh Chelgani, S. Matin, and J. C. Hower, “Explaining relationships between coke quality index and coal properties by random forest method,” Fuel, vol. 182, pp. 754 – 760, 2016. https://doi.org/10.1016/j.fuel.2016.06.034

[38] R. Morga, I. Jelonek, K. Kruszewska, and W. Szulik, “Relationships between quality of coals, resulting cokes, and micro-raman spectral characteristics of these cokes,” International Journal of Coal Geology, vol. 144-145, pp. 130 – 137, 2015. https://doi.org/10.1016/j.coal.2015.04.006

[39] R. J. Gray, “Some petrographic applications to coal, coke and carbons,” Organic Geochemistry, vol. 17, no. 4, pp. 535 – 555, 1991. https://doi.org/10.1016/0146-6380(91)90117-3

[40] T. Gentzis and P. Rahimi, “A microscopic approach to determine the origin and mechanism of coke formation in fractionation towers☆,” Fuel, vol. 82, no. 12, pp. 1531 – 1540, 2003. https://doi.org/10.1016/S0016-2361(03) 00032-2

[41] C. Barriocanal, S. Hanson, J. W. Patrick, and A. Walker, “The characterization of interfaces between textural components in metallurgical cokes,” Fuel, vol. 73, no. 12, pp. 1842 – 1847, 1994. https://doi.org/10.1016/0016-2361(94)90209-7

[42] M. Lundgren, L. Sundqvist Ökvist, and B. Björkman, “Coke reactivity under blast furnace conditions and in the csr/cri test,” steel research international, vol. 80, no. 6, pp. 396–401, 2009. https://onlinelibrary.wiley. com/doi/abs/10.1002/srin.201090020

[43] D. Vogt and M. Depoux, “Coke reactivity prediction by texture analysis,” Fuel Processing Technology, vol. 24, pp. 99 – 105, 1990, coal Characterisation for Conversion Processes II. https://doi.org/10.1016/0378-3820(90)90046-U